Overture ABS Orca Slicer Profile with Raft:The Ultimate Guide to ASA & ABS 3D Printing

Overture ABS filament is a trusted choice among 3D printing enthusiasts due to its strength, heat resistance, and post-processing capabilities. However, printing ABS can be tricky due to issues like warping and bed adhesion. This is where a well-tuned Orca Slicer profile and raft setting can make all the difference.

Overture ABS Orca Slicer Profile

3D printing with ABS and ASA filaments can be incredibly rewarding, especially if you’re using premium materials like Overture ABS and slicing with Orca Slicer on advanced machines like the Bambu X1C. However, getting your 3D print to look professional and durable requires optimized settings and an understanding of how various filament types behave. In this guide, we’ll deep dive into building the best ABS Orca Slicer profile with raft, tuning your flow calibration, and mastering ASA and ABS printing.

Understanding ABS and ASA Filament for 3D Printing

ABS (Acrylonitrile Butadiene Styrene) and ASA (Acrylonitrile Styrene Acrylate) are popular 3D printer filament choices due to their strength, heat resistance, and professional finish. While ABS has been widely adopted for functional prototypes, ASA filament brings improved UV resistance, making it ideal for outdoor applications. If you’ve been printing with PLA filament, switching to ABS or ASA requires updated print profiles, extrusion rates, and print temperatures.

Why Print with Overture ABS?

Whether you’re a hobbyist or a professional, optimizing your ABS slicer settings is critical. In this guide, we’ll dive into how to fine-tune your Orca Slicer settings for Overture ABS filament—including the strategic use of a raft to minimize warping and improve print success.

Why Use a Raft with Overture ABS?

ABS filament tends to warp due to its high shrinkage rate. Using a raft helps improve bed adhesion and reduce warping. Especially with Bambu 3D printers like the Bambu X1C or P1P, combining a well-tuned raft setting in Orca Slicer with materials like Polymaker ASA or Overture ABS gives consistent first layers and smooth prints.

What Makes ABS Challenging to Print?

ABS (Acrylonitrile Butadiene Styrene) offers durability but is sensitive to environmental factors. Here’s what you need to tackle:

- Warping on corners and edges

- Poor first-layer adhesion

- Inconsistent layer bonding

- Nozzle clogging at low temps

The solution? An optimized Orca slicer profile with raft support, temperature control, and bed preparation.

Recommended Orca Slicer Profile Settings for Overture ABS

Here’s a breakdown of ideal ABS print settings for Overture filament using Orca Slicer.

1. Temperature Settings

- Nozzle Temp: 240°C – 250°C

- Bed Temp: 100°C – 110°C

- Chamber Temp (if available): 45°C – 60°C

2. Print Speed

- Default Print Speed: 40–60 mm/s

- First Layer Speed: 15–20 mm/s for optimal bed adhesion

3. Cooling Fan

- Layer Fan: Off for the first 5 layers, then low (10% max)

→ Helps avoid warping without compromising layer fusion.

4. Retraction Settings

- Distance: 1.5 mm

- Speed: 35–45 mm/s

→ Prevents stringing while avoiding nozzle clogs.

Downloadable 3D print profiles, STL files, and 3MF slicer files for Orca are available on platforms like Printables by Prusa, Thingiverse, and MyMiniFactory

Why Use a Raft with ABS?

Using a raft when printing with ABS—especially with Overture ABS—is a powerful way to:

- Improve bed adhesion

- Minimize warping

- Level out surface irregularities on your build plate

- Act as a heat barrier for the first few layers

This is particularly useful if you’re printing large flat-bottomed parts or using an unheated enclosure.

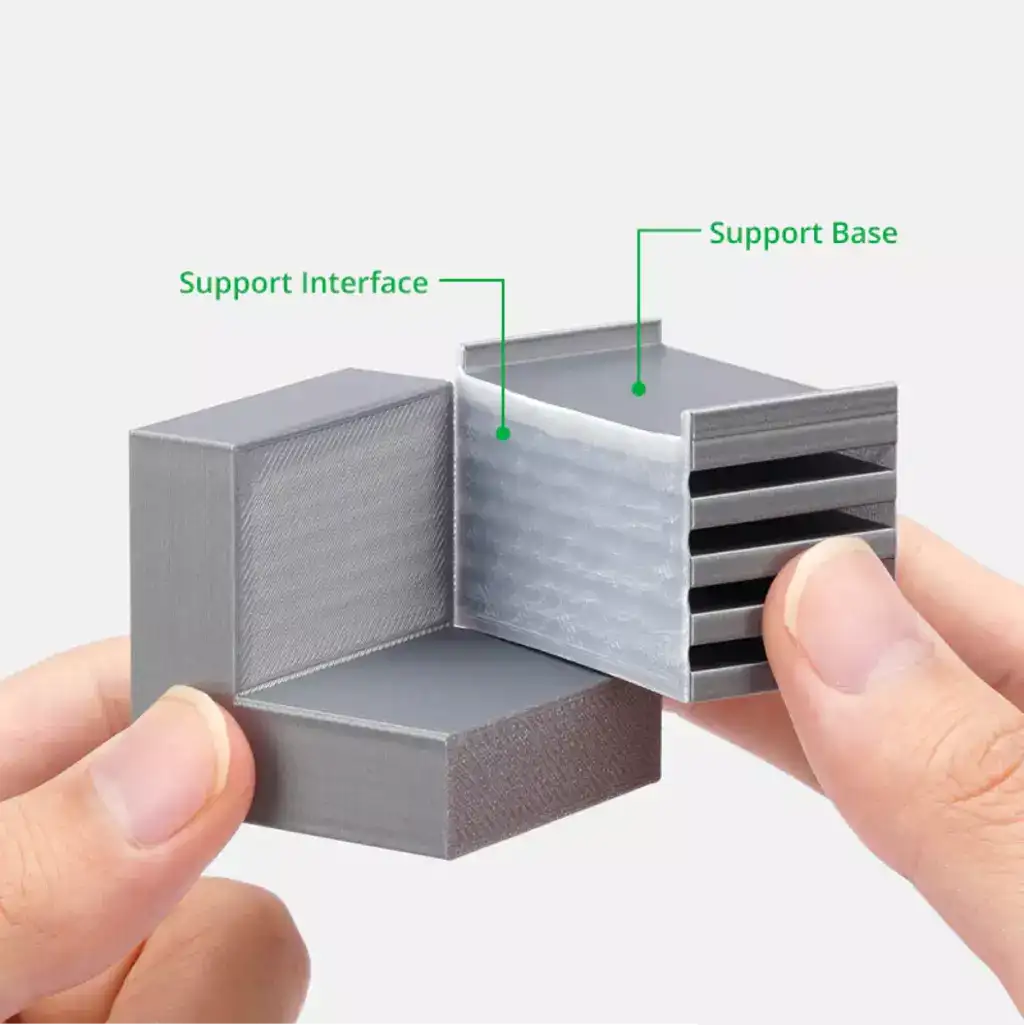

Best Raft Settings in Orca Slicer for Overture ABS

Here’s how to configure your raft in Orca Slicer:

| Setting | Recommended Value |

|---|---|

| Raft Layers | 3–4 |

| Raft Air Gap | 0.25 mm |

| Raft Top Layer Speed | 15 mm/s |

| Raft Expansion | 5 mm |

| Raft Temperature | Same as bed/nozzle temp |

✅ Pro Tip: Enable “brim around raft” if the part still shows signs of lifting.

Best Practices for Printing ASA Filament

When printing with ASA filament, be mindful of its higher printing temperature (240°C–260°C) and slightly more brittle nature. ASA 3D printing filament prints better with:

- Minimal fan speed

- Higher bed temperatures

- Enclosed chamber

- Slower print speeds

- Proper ASA filament print settings

Use models like Polymaker PolyLite ASA and adjust settings using a filament slicer.

Additional Tips for Success with Overture ABS

- Use an Enclosure: Prevent temperature fluctuations.

- Clean Bed Surface: Use isopropyl alcohol to clean glass or PEI sheets.

- Apply Adhesion Helpers: ABS slurry, Magigoo, or glue stick can enhance grip.

- Avoid Drafts: Even small airflows can cause delamination.

Accurate flow calibration is essential for successful prints with ABS or ASA. Print a test model and measure wall thickness to compare with expected values. This prevents under- or over-extrusion. Also, measure shrinkage to adjust your 3D model slicer settings accordingly.

Pro tip: Use the 3D print calibration guide in Orca Slicer or Bambu Studio.

Top 3D Printer Filament Brands for ABS & ASA

Recommended brands:

- Overture ABS: Consistent quality and minimal warping.

- Polymaker ASA: Great for weatherproof outdoor parts.

- eSUN, Sunlu: Budget-friendly options.

Explore different filament brands, filament settings, and PLA/ABS/PETG options for diverse needs.

Where to Get the Best 3D Print Files

Find printables, STL file models, 3MF downloads, and more from sites like:

- Printables (Prusa)

- Thingiverse

- Cults3D

Look for tags like 3D ABS, ASA 3D, or ABS 3D model to find specific files.

Best Printers for ABS & ASA: Orca Slicer & Bambu X1C and Beyond

If opting for Best 3D Printers for successful ABS/ASA printing, the Orca Slicer & Bambu X1C 3D printer is a top choice with features like:

- Active chamber heating

- Auto bed leveling

- Multi-material support

Combine this with a Bambu slicer or Orca Slicer to tweak your 3D print profiles to perfection.

Summary: Optimizing Your ABS/ASA Workflow

- Use rafts for better adhesion

- Tune your flow rate and temperature settings

- Choose the right 3D printer slicer

- Calibrate often

- Pick top-tier filament types and brands

Whether you’re printing functional parts, miniatures, or outdoor components, mastering your ABS Orca Slicer profile with raft setup will dramatically improve your results.

Stay up to date with the latest improvements by following this quick guide on how to update Orca Slicer.

Conclusion

Setting up the perfect Orca Slicer profile for Overture ABS—with a raft enabled—can significantly improve your print success rate. From precise temperatures to raft configurations, every detail matters when it comes to printing ABS.

Investing time in slicer calibration and using a raft where needed ensures better adhesion, fewer failed prints, and stronger finished parts. Start with the settings in this guide and fine-tune for your specific machine.

Ready to print? Download your STL models, fine-tune your extrusion rate, and start printing with confidence.

Frequently Asked Questions

Is Overture ABS beginner-friendly?

It’s more advanced than PLA but manageable with the right settings and a raft.

Can I print Overture ABS without a raft?

Yes, but you’ll need excellent bed adhesion and an enclosure. Raft makes things easier.

What’s the best bed surface for ABS?

Glass with ABS slurry or a PEI sheet with glue stick works well.

What is the best slicer profile for printing Overture ABS with raft on a Bambu X1C?

The best slicer profile combines a 240–260°C nozzle temp, 100–110°C bed temp, flow rate calibration, and a raft enabled with a slight Z-offset. Orca Slicer or Bambu Studio profiles optimized for Overture ABS filament ensure proper adhesion and warp-free prints.

Why does ABS filament need a raft when 3D printing?

ABS has a high shrinkage rate that can cause warping. Using a raft in Orca Slicer improves bed adhesion and prevents edge lifting—especially useful for large flat prints on enclosed 3D printers like the Bambu X1C.

Can I print ASA filament using the same Orca Slicer profile as ABS?

While similar, ASA filament requires fine-tuning—higher temps, lower fan speeds, and slower print speeds. You should create a dedicated ASA profile in Orca Slicer to adjust for these differences and improve print reliability.

What are the best temperature settings for ABS in Orca Slicer?

Start with a nozzle temp of 245°C–255°C, a heated bed at 100°C, and enable a raft for enhanced adhesion. These values may vary slightly depending on your ABS filament brand and 3D printer setup.

How do I calibrate the flow rate for ABS and ASA filaments?

Use flow rate calibration cubes or test prints in Orca Slicer to check wall thickness against design specs. Adjust extrusion multiplier accordingly to prevent over- or under-extrusion. Calibration is key for high-quality ABS or ASA prints.

What are the top ABS and ASA filament brands for 3D printing?

Recommended brands include:

Overture ABS – known for consistency and minimal warping

Polymaker ASA – excellent UV and weather resistance

eSUN, Sunlu – reliable and budget-friendly options

Which 3D printers are best for ABS and ASA printing?

Enclosed 3D printers like the Bambu X1C, Bambu P1P, or Prusa MK4 (with enclosure) are ideal. Features like chamber heating, auto-leveling, and good part cooling are crucial for successful ABS/ASA prints.

Where can I download 3D print files optimized for ABS or ASA?

Find ABS/ASA-compatible STL and 3MF files on:

Printables by Prusa

Thingiverse

MyMiniFactory

Cults3D

Use tags like ASA 3D, ABS 3D model, or ABS Orca Slicer profile for best results.

Is a raft always necessary when printing ABS?

While not mandatory, using a raft is highly recommended for large or flat ABS prints, especially when warping is a concern. It ensures the first layers adhere well, reducing failed prints on materials like glass or textured PEI beds.

What’s the difference between ABS and ASA filament for 3D printing?

Both offer strength and heat resistance, but ASA filament provides better UV stability, making it suitable for outdoor use. ABS is slightly tougher, while ASA has a cleaner surface finish and doesn’t yellow in sunlight.

How do I add a custom profile to Orca Slicer?

To add a new profile in Orca Slicer, open the software, go to the Printer Settings tab, click Import, and upload your .3mf or .json file. You can also copy and tweak an existing profile by saving it under a new name. Make sure to match it to your printer model and filament type like Overture ABS or Polymaker ASA.

Is Orca Slicer free to use?

Yes! Orca Slicer is an open-source, community-driven slicer built on Bambu Studio. It’s completely free and supports powerful features like flow rate calibration, pressure advance, and multi-material handling for printers like Bambu X1C, P1P, and others.

What are the best settings for ABS printing in Orca Slicer?

For ABS printing, ideal settings include:

Nozzle temp: 245–255°C

Bed temp: 100–110°C

Chamber: Enclosed preferred

Print speed: 40–60mm/s

Cooling fan: Off or minimal

Use a raft for better bed adhesion, especially with Overture ABS filament.

Is Overture PLA food safe?

Overture PLA is not officially FDA-approved as food-safe. While PLA itself is considered non-toxic, additives, dyes, and the printing process (especially on brass nozzles) can introduce contaminants. Use food-safe coatings or FDA-compliant materials if safety is a concern.

Where can I download the Overture ABS Orca Slicer profile?

You can download Overture ABS profiles for Orca Slicer from:

Community forums like Reddit r/FixMyPrint

Printables (Prusa)

GitHub slicer repositories

Or reach out directly to Overture or use our custom-made profile!

Is there a Reddit community for Overture ABS Orca Slicer profiles?

Yes, Reddit users often share and troubleshoot Overture ABS profiles on subs like:

r/FixMyPrint

r/BambuLab

r/3Dprinting Search for threads titled “Overture ABS Orca Slicer profile” or “best Bambu Studio settings for ABS.”

Where can I find all Overture filament profiles?

Official Overture filament profiles can be found on:

Overture’s Amazon product listings

Their official support page

Cura Marketplace (for PLA and PETG)

Community-sourced profiles on Reddit and Thingiverse for ABS, PLA, and ASA

Is there a Cura profile for Overture PETG?

Yes, you can import or create a custom Cura profile for Overture PETG with the following baseline:

Nozzle Temp: 240–250°C

Bed Temp: 80–90°C

Fan: On (50–100%)

Retraction: 5mm at 40mm/s

Also, enable a brim or raft to avoid warping.

What are the best filament settings for Overture materials?

Filament settings vary by material:

PLA: 200–210°C, 60°C bed

ABS: 245–255°C, 100°C bed, enclosed

PETG: 240–250°C, 80°C bed

ASA: 250–260°C, 100°C bed

Adjust retraction, cooling, and flow rate accordingly in your slicer.

Does Bambu Lab support Overture filament profiles?

While Bambu Lab AMS does not come preloaded with Overture profiles, you can manually create them in Bambu Studio or Orca Slicer. Use the material card or edit custom filament presets for Overture ABS, PLA, or ASA.

Is Overture Black ASA good for outdoor use?

Yes, Overture Black ASA is UV-resistant, weatherproof, and built for outdoor applications. It’s comparable to Polymaker ASA in strength and stability, making it a great choice for enclosures, brackets, and signage.

Is Polymaker ABS a good alternative to Overture?

Absolutely. Polymaker ABS is known for high dimensional accuracy, low warping, and strong mechanical properties. While it may be slightly pricier than Overture ABS, it’s often used by professionals needing high repeatability and finish quality.

How do I add a profile in Orca Slicer?

Go to Configuration > Profiles, then click Add or Import to create or upload a new printer, filament, or print profile.

What are the best settings for Orca Slicer seams?

Use Seam Position: Rear or Aligned for clean finishes. Set Seam Gaps to 0, enable Random Seam, and fine-tune retraction to reduce marks.

Is the Orca Slicer compatible?

Yes, Orca Slicer works with most FDM printers, including Creality, Bambu Lab, Prusa, and Voron, and supports Marlin, Klipper, and Duet firmware.

Is Orca a good slicer?

Yes, Orca Slicer is a is a powerful, user-friendly slicer with advanced features and great print quality. It’s ideal for both beginners and pros.