Orca Slicer Interface: A Deep Dive into the Most Powerful UI in 3D Printing

The Orca Slicer Interface has quickly gained a reputation as one of the most intuitive, efficient, and customizable slicer interfaces in the 3D printing ecosystem. Built upon the powerful Bambu Studio and PrusaSlicer foundations, Orca Slicer delivers a rich set of interface controls and advanced features that appeal to both hobbyists and professionals.

In this article, we’ll explore the Orca Slicer user interface, including its support interface, web interface, layer interface, and top interface layers, all while incorporating critical semantic keywords for optimized technical discovery.

Orca Slicer Interface

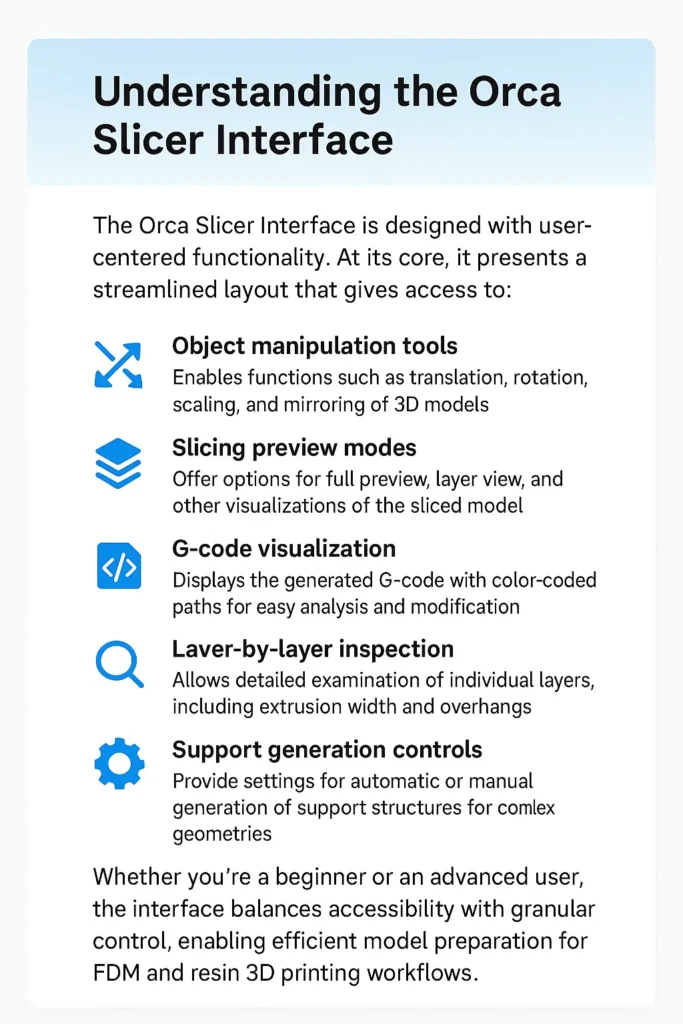

The Orca Slicer Interface is designed with user-centered functionality. At its core, it presents a streamlined layout that gives access to:

- Object manipulation tools

- Slicing preview modes

- G-code visualization

- Layer-by-layer inspection

- Support generation controls

The Orca Slicer Interface is designed with user-centered functionality, combining a modern GUI framework with backend slicing engines optimized for both Fused Deposition Modeling (FDM) and Masked Stereolithography (MSLA) workflows. At its core, it presents a streamlined layout that gives access to:

- Object Manipulation Tools

Includes translation (XYZ-axis movement), uniform and non-uniform scaling, model rotation (Euler angles), and mirror operations. These allow precise model positioning on the build plate and alignment with part orientation strategies for optimal mechanical strength and surface finish. - Slicing Preview Modes

Offers various rendering modes such as solid preview, line-type visualization, and color-coded view based on print speed, flow rate, or feature type (e.g., infill, perimeter, bridge, support). These help in fine-tuning parameters before generating G-code. - G-code Visualization

Displays toolpath trajectories layer-by-layer, with speed and extrusion width overlays. Users can simulate printhead movements and detect errors like travel collisions or under-extruded regions. G-code is fully editable within the interface for manual tweaks. - Layer-by-Layer Inspection

Enables incremental slicing analysis, letting users inspect Z-height resolution, extrusion width, shell thickness, overhang angles, and support thresholds. This is crucial for identifying delamination risks or poor overhang coverage. - Support Generation Controls

Provides automatic or customizable support interface generation using tree-like or linear structures. Key configurable parameters include:- Support Interface Material

- Support Interface Speed

- Fan Speed for Support Interface

- Interface Pattern Type (zigzag, concentric, grid)

- Top Interface Layers for improved base adhesion These settings affect support detachability, print time, and material efficiency.

Key Features:

- Minimalist UI with collapsible panels

- Real-time slicing feedback

- Visual timeline for layer transitions

- Material and speed tuning tabs

Additional Technical Conditions for Optimal Use – Orca Slicer Interface

Additional Technical Conditions for Optimal Use – Orca Slicer Interface

| Category | Details |

|---|---|

| Minimum System Requirements | • CPU: Quad-core 2.5GHz or higher • RAM: 8 GB minimum • GPU: OpenGL 4.1-compatible • Disk: SSD recommended for faster slicing speed |

| Recommended Firmware | Compatible with: • Klipper • Marlin • RepRap-based firmware Note: G-code post-processing may vary by firmware type. |

| G-code Output Customization | • Embed conditional macros: M117, M600, G28, G92 • Insert custom pause, filament change, or prime routines • Configure retraction, z-hop, and coasting for anti-stringing |

| Material Profiles | Built-in presets for: • PLA, ABS, PETG, TPU, Nylon, ASA • Fully adjustable: print temperature, cooling rate, interface adhesion layers |

| Web Interface Access | • LAN or remote slicer access via browser • Upload STL files remotely • Real-time monitoring of slicing status |

| Versioning & Updates | • Frequent updates include bug fixes and slicing optimizations • Auto-backup enabled for profiles and custom presets |

Orca Slicer Interface Layer Preview: Precision Visualization

The Orca Slicer Interface Layer view is crucial for inspecting how each layer will be printed. It allows users to:

- Analyze extrusion paths

- View per-layer infill and perimeter

- Detect under-supported overhangs

- Adjust Z-seam alignment

This mode ensures users can preemptively address structural concerns before printing, minimizing print failures and optimizing layer adhesion.

Orca Slicer Interface Layer Preview: Technical Features Table

| Feature | Description | Technical Benefit |

|---|---|---|

| Extrusion Path Analysis | Visualizes toolpath trajectories for perimeters, infill, bridges, and supports. | Identifies travel inefficiencies, gaps between shells, and flow-related issues. |

| ➤ Redundant Travel Moves | Highlights non-essential movements between islands or parts. | Reduces print time and stringing. |

| ➤ Incomplete Infill Paths | Detects issues due to incorrect flow rate or extrusion width. | Ensures proper part strength and coverage. |

| Per-Layer Visualization | Displays shells, solid layers, infill types (grid, gyroid, cubic), and bridge placement. | Allows real-time print structure analysis per layer. |

| ➤ Shell Configuration | Shows number of perimeters, top/bottom layers. | Optimizes surface finish and mechanical strength. |

| ➤ Bridging Angles | Visualizes orientation and placement of bridge material. | Prevents sagging in unsupported regions. |

| Overhang Detection | Highlights overhangs above critical threshold (e.g., 45°). | Prompts support placement or design changes for better surface finish. |

| Z-Seam Alignment Tool | Allows Z-seam to be positioned at sharp corners, rear, random, or manually. | Minimizes seam visibility and improves aesthetics. |

| ➤ Seam Modes | Sharpest corner, back side, randomized, custom coordinates. | Customizes for cosmetic or functional part needs. |

| Print Speed Heat Map | Color-codes print regions by speed, extrusion width, and acceleration. | Helps visualize and optimize consistent surface quality and layer bonding. |

| Retraction & Travel Visualization | Shows retraction points, Z-hop, and travel moves between parts. | Enables stringing reduction, travel path efficiency, and clean transitions. |

| ➤ Retraction Settings | Adjust retraction length/speed and z-hop lifts. | Prevents oozing and improves travel path cleanliness. |

| ➤ Island Hopping Optimization | Visualize and avoid unnecessary movements between separate print areas. | Enhances speed and reduces errors. |

| Live G-code Inspector | Hover over G-code in preview to inspect commands (e.g., M117, G92), extrusion values, speeds. | Useful for debugging or custom post-processing. |

Pro Tips for Power Users

| Advanced Technique | Functionality | Benefit |

|---|---|---|

| Feature Type Coloring Mode | Differentiates perimeters, infill, supports, gaps, and bridges with unique colors. | Enhanced visual inspection and debugging. |

| Dynamic Extrusion & Layer Height | Adjusts extrusion width and layer height by model region. | Balances strength vs. fine detail. |

| Variable Layer Height Mode | Increases Z-resolution in curved regions, reduces detail in flat zones. | Saves print time without losing quality. |

The Layer Preview Mode in Orca Slicer is a pivotal tool in the slicing workflow, offering a layer-by-layer breakdown of the G-code. This view enables technical inspection of how each slice of the model will be processed by the printer, particularly useful for diagnosing and improving part reliability and visual quality.

💡 Pro Tips for Advanced Users:

- Use the “feature type coloring mode” to distinguish between perimeters, infill, supports, bridges, and gaps.

- Adjust extrusion width and layer height dynamically to balance strength and resolution in specific zones.

- Leverage variable layer height mode to increase detail on curved surfaces while speeding up flat sections.

Mastering the Orca Slicer Support Interface

The Orca Slicer Support Interface is a standout feature, offering precision control over how supports are generated and interact with the printed model.

Customizable Settings Include:

- Support interface pattern (zigzag, grid, concentric)

- Support interface speed for reduced print time

- Support interface fan speed for layer cooling efficiency

- Support interface material assignment (ideal for dual extrusion)

- Support interface settings such as density, offset, and spacing

Mastering the Orca Slicer Support Interface – Technical Settings Table

| Support Feature | Description | Technical Benefit |

|---|---|---|

| Support Interface Pattern | Choose from Zigzag, Grid, or Concentric patterns for the contact layer between the support and the model. | Improves interface strength and ease of removal depending on surface geometry. |

| ➤ Zigzag | Quick, linear pattern for faster print times. | Easy to remove and ideal for overhangs. |

| ➤ Grid | Criss-cross pattern providing robust support. | Better support for larger flat surfaces. |

| ➤ Concentric | Circular or edge-following pattern. | Excellent for curved or contoured surfaces. |

| Support Interface Speed | Sets the speed for printing only the interface layer. | Faster print with minimal compromise to surface quality. |

| ➤ Tunable Speed | Adjust independently from support body speed. | Helps fine-tune interface adhesion and print time. |

| Support Interface Fan Speed | Dedicated cooling fan control during support interface printing. | Improves bridging quality and surface transition at interface contact. |

| ➤ Full Cooling Activation | Enables 100% fan for better solidification. | Reduces sagging and improves overhangs. |

| Support Interface Material Assignment | In dual extrusion setups, allows use of a separate material for interface layers (e.g., soluble material). | Enables clean separation and easy support removal. |

| ➤ PVA or HIPS as Soluble Interface | Can be used with PLA/ABS to dissolve supports in water or limonene. | Ideal for complex geometries and professional-grade finishes. |

| Support Interface Density | Determines how dense the contact layer is between support and model. | Higher density = stronger but harder to remove; lower density = easier removal. |

| Support Interface Z-Offset | Controls the vertical distance (air gap) between the model and the support interface. | Adjusts bonding strength vs. removability. |

| ➤ Typical Offset | 0.2 – 0.3 mm recommended for breakaway support. | Prevents fusion while maintaining structural support. |

| Support Interface Spacing & Gap Settings | Adjust horizontal spacing and gap between support walls and the print. | Avoids support scars and improves surface finish. |

Expert Tips for Support Optimization

| Technique | How It Works | Why It Matters |

|---|---|---|

| Enable Tree Supports for Complex Prints | Generates branched, minimal-contact supports. | Reduces material use and scarring on organic or detailed shapes. |

| Custom Support Painting | Manually paint support zones directly on the model. | Offers precise control, reduces unnecessary support material. |

| Combine with Variable Support Density | Increase support density near critical overhangs while reducing it elsewhere. | Saves print time and enhances part finish where it counts most. |

| Use Interface Only Mode | Disables full supports, leaving just the interface layer where needed. | Great for prints requiring minimal support but crucial surface quality. |

These parameters allow for strong, easily removable support structures that don’t damage the model’s surface.

Orca Slicer Top Interface Layers: Enhancing Surface Finish

Top interface layers play a critical role in the final look of your model’s upper surfaces. Orca Slicer allows you to define:

- Top layer count

- Ironing patterns

- Top skin overlap

- Speed modifiers for surface smoothing

Orca Slicer’s Top Interface Layers

| Setting | Description | Practical Tip |

|---|---|---|

| Top Layer Count | Defines the number of topmost layers printed. More layers provide a smoother surface. | Increase the top layer count to cover imperfections from lower layers, ensuring a polished and uniform finish. |

| Ironing Patterns | The nozzle moves across the top layers to smooth the surface, reducing layer lines. | Enable ironing for a glossy or smoother surface, especially for prints where aesthetics are important (e.g., PLA). |

| Top Skin Overlap | Determines how much the outermost layers overlap with the interior infill. A higher overlap improves adhesion. | Increase overlap to reduce gaps and ensure better bonding between top layers and infill, leading to a more seamless surface. |

| Speed Modifiers | Adjusts the printing speed for top layers to improve surface smoothing. | Reduce the print speed for top layers to achieve finer, smoother finishes on the model’s upper surface. |

| Material Selection | Different materials affect surface finish quality. | Use PLA or PETG for easier smooth finishes. For tougher materials like ABS or Nylon, fine-tune other settings. |

| Temperature Settings | Higher temperatures can improve layer adhesion but may increase stringing or oozing. | Adjust temperature settings according to the filament used to maintain good layer adhesion while avoiding surface defects like stringing. |

By adjusting the top interface layers, users can improve surface quality and minimize visual imperfections like layer lines or under-extruded patches.

Orca Slicer Web Interface: Remote Control & Monitoring

The Orca Slicer Web Interface introduces a new level of connectivity to your 3D printing setup. Compatible with select firmware and OctoPrint environments, it lets users:

- Upload sliced models remotely

- Monitor print progress in real-time

- Adjust fan speed, temperature, and flow rate

- Access webcam and failure alerts

Orca Slicer Web Interface: Remote Control & Monitoring

| Feature | Description | Practical Benefits |

|---|---|---|

| Remote Model Upload | Allows users to upload sliced models directly from their computer or cloud storage to the 3D printer remotely. | – Convenience: Start prints from anywhere without needing to be near the printer. – Time Efficiency: Upload and set up prints without interruption. – Multi-Printer Management: Manage multiple printers from a single interface. |

| Real-time Print Monitoring | Provides real-time monitoring of print progress, displaying print time, remaining time, and layer height. | – Visual Feedback: Keep track of print progress remotely, spotting issues early. – Proactive Issue Management: Quickly identify problems like misalignment or material exhaustion. – Track Prints from Anywhere: Monitor prints from any location with internet access. |

| Adjustable Print Settings | Allows on-the-fly adjustments to fan speed, extruder temperature, and flow rate during the print. | – Enhanced Print Quality: Fine-tune settings for better finish. – Minimize Failures: Adjust settings to address issues as they arise. – Customization: Adjust settings for specific materials or print regions. |

| Webcam Access | Enables users to monitor print progress via a connected webcam, displayed through the web interface. | – Visual Monitoring: Observe the print in real-time for better quality control. – Peace of Mind: Check print progress from anywhere without being near the printer. – Enhanced Control: Get a clear understanding of print quality by watching it live. |

| Failure Alerts | Sends notifications for print failures, filament run-out, or other issues. Alerts can be sent via mobile or email. | – Instant Notifications: Get notified as soon as something goes wrong, such as extrusion issues or print failure. – Minimized Downtime: Address issues immediately to avoid wasting material and time. – Improved Efficiency: Stay updated on print status without needing to manually check the printer. |

This web-based interface adds convenience for remote teams, print farms, and educational labs.

Advanced Slicer Interface Settings: Fine-Tuning Print Performance

Orca Slicer empowers users to dive into detailed interface settings with custom profiles. Key parameters include:

- Support interface material flow rate

- Interface offset to improve support adhesion

- Dynamic support interface fan speed

- Pattern types for variable strength and flexibility

Advanced Slicer Interface Settings in Orca Slicer for Fine-Tuning Print Performance:

| Setting | Description | Practical Benefits |

|---|---|---|

| Support Interface Material Flow Rate | Controls the flow rate of material used in the interface between support and the model. | – Improved Support Adhesion: Adjusting the flow rate ensures that the support material adheres well to the model. – Efficient Material Use: Fine-tune to avoid excessive use of support material while maintaining strong adhesion. – Optimal Support Performance: Prevents weak support structures that could affect the quality of the print. |

| Interface Offset for Support Adhesion | Adjusts the offset distance between the support structure and the model’s surface to improve adhesion. | – Better Adhesion: An optimal offset can enhance adhesion between the model and support, preventing print failures. – Easier Support Removal: Finding the right offset allows for better separation between support and model, making post-processing easier. – Prevention of Warping: A proper interface offset reduces the chance of warping during the print process. |

| Dynamic Support Interface Fan Speed | Controls the fan speed specifically for the support interface areas. It helps manage cooling during the printing of support structures. | – Improved Support Quality: Adjust fan speed for optimal cooling of support structures, reducing sagging or deformation. – Faster Print Times: Dynamic fan control helps cool support material more quickly, leading to faster print times. – Increased Print Accuracy: Proper cooling ensures more precise and stable support structures, reducing the likelihood of misprints. |

| Pattern Types for Variable Strength and Flexibility | Allows users to choose different support interface pattern types (e.g., grid, honeycomb, lines) for varying levels of strength and flexibility. | – Customizable Support Performance: Choose a pattern that balances strength and flexibility based on the needs of your print. – Better Strength: Opt for stronger patterns (like grid) for heavy or large models. – Easier Removal: Use flexible patterns (like lines) for easier post-processing and better support removal. – Material Efficiency: Choose the pattern that provides the necessary support with minimal material usage. |

1. Support Interface Material Flow Rate

To understand more about material flow rates and settings for optimal 3D printing, you can refer to the following links for related resources:

- Filament Settings: This article provides an in-depth look at various filament settings that complement the support interface material flow rate for better print performance.

- Orca Slicer PETG Profile: Learn about the best settings for PETG filament, which is particularly useful for fine-tuning the flow rate for support structures.

2. Interface Offset for Support Adhesion

Proper interface offset can significantly enhance adhesion between the model and support structures. For more details, refer to the following:

- Printer Selection: Choosing the right printer can impact support adhesion, and this article can help you select a printer that works best with Orca Slicer settings.

- Best 3D Printers Compatible with Orca Slicer: Find out which 3D printers are most compatible with Orca Slicer and how they can improve your print quality and support adhesion.

3. Dynamic Support Interface Fan Speed

Adjusting the fan speed for support areas is crucial for print quality. For relevant details, you can check out these articles:

- Orca Slicer vs Qidi Slicer: Learn how Orca Slicer compares to other slicers like Qidi Slicer, which also offer dynamic fan control for optimal cooling and print quality.

- Orca Slicer Not Working: If you’re facing issues with the fan speed or other slicer settings, this article can guide you on troubleshooting and fixing common problems.

4. Pattern Types for Variable Strength and Flexibility

Pattern types are essential for optimizing support structures. For more information on patterns and print settings, refer to the following:

- Overture ABS Orca Slicer: Explore the different settings for ABS filament and how choosing the right pattern type can impact strength and flexibility during the print process.

- Orca vs Creality vs Bambu Studio: This article compares Orca Slicer with other slicers, helping you understand which pattern types work best with various slicers.

5. General Settings and Troubleshooting

For troubleshooting and general settings, refer to these related articles:

- Update Orca Slicer: Ensure you’re using the latest version of Orca Slicer for improved features and bug fixes that can help with fine-tuning your settings.

- Calibration Guide: Proper calibration is essential for achieving optimal print results. This guide helps you calibrate your printer for improved accuracy when adjusting slicer settings.

Practical Application of Fine-Tuning Settings

These advanced slicer settings allow users to make trade-offs between speed, print quality, and support removal, giving complete control over the print performance. By carefully adjusting the support interface material flow rate, interface offset, fan speed, and support pattern types, users can optimize prints for different material types, print sizes, and specific use cases.

Whether you are printing large, complex models with intricate support structures or aiming for a quick print with minimal post-processing, these settings ensure that Orca Slicer can meet your exact requirements.

These fine controls let users optimize for speed, quality, or support removal depending on the project’s demands.

Final Thoughts

The Orca Slicer Interface stands as one of the most adaptable and powerful UIs in the world of 3D printing. From its support interface sophistication to its layer previewing tools and web control capabilities, Orca Slicer ensures a seamless experience from model import to print execution.

For serious 3D printing enthusiasts, mastering the Orca Slicer support interface, top interface layers, and advanced slicing configurations is the key to producing high-quality prints with consistency and efficiency.

Frequently Asked Questions

What is the Orca Slicer Interface?

The Orca Slicer interface is the user dashboard that allows full control over slicing, printer settings, preview modes, and remote connectivity features for enhanced 3D print management.

How to Download the Orca Slicer Interface?

You can download the Orca Slicer interface from the official website orcaslicer.pro. It supports Windows, macOS, and Linux systems.

Where to Get the Orca Slicer Download?

Visit orcaslicer.pro for the latest Orca Slicer download, including stable and beta versions for advanced users.

What Is the Orca Slicer Web Interface?

The Orca Slicer web interface allows users to monitor and control their printers remotely, access webcams, receive failure alerts, and adjust live print settings over a browser.

Why Does the Orca Slicer Device Tab Refuse to Connect?

If the device tab refused to connect, ensure your printer is on the same network, OctoPrint/firmware is compatible, and try restarting both Orca and the printer.

Where to Find the Orca Slicer Interface Manual?

The Orca Slicer interface manual is available under the help/support section on orcaslicer.pro, offering setup guides and interface walkthroughs.

Why is the Orca Slicer Device Tab Not Working?

If your device tab is not working, it might be due to network issues or firmware incompatibility. Update software and check your connection settings.

Why is the Orca Slicer Device Tab Blank?

A blank device tab often indicates a failed connection to the printer. Confirm device IP, reboot Orca Slicer, and ensure all firmware plugins are active.

Is Orca Slicer Available on Android?

There is no official Orca Slicer Android app, but users can access the web interface on Android browsers for remote monitoring and control.

What is the Device UI in Orca Slicer?

The Device UI in Orca Slicer lets users control and monitor 3D printer settings (e.g., temperature, fan speed) directly through the software, offering real-time adjustments for better print control.

Is Orca Slicer Better than Cura?

Orca Slicer offers advanced features for custom control and fine-tuning, while Cura is more beginner-friendly. Orca is ideal for users seeking more precision and professional-level adjustments.

Is OrcaSlicer.com Safe?

Yes, OrcaSlicer is a safe, official source for downloading the software. Always ensure to download from the official website to avoid third-party risks.